Project Info

Date

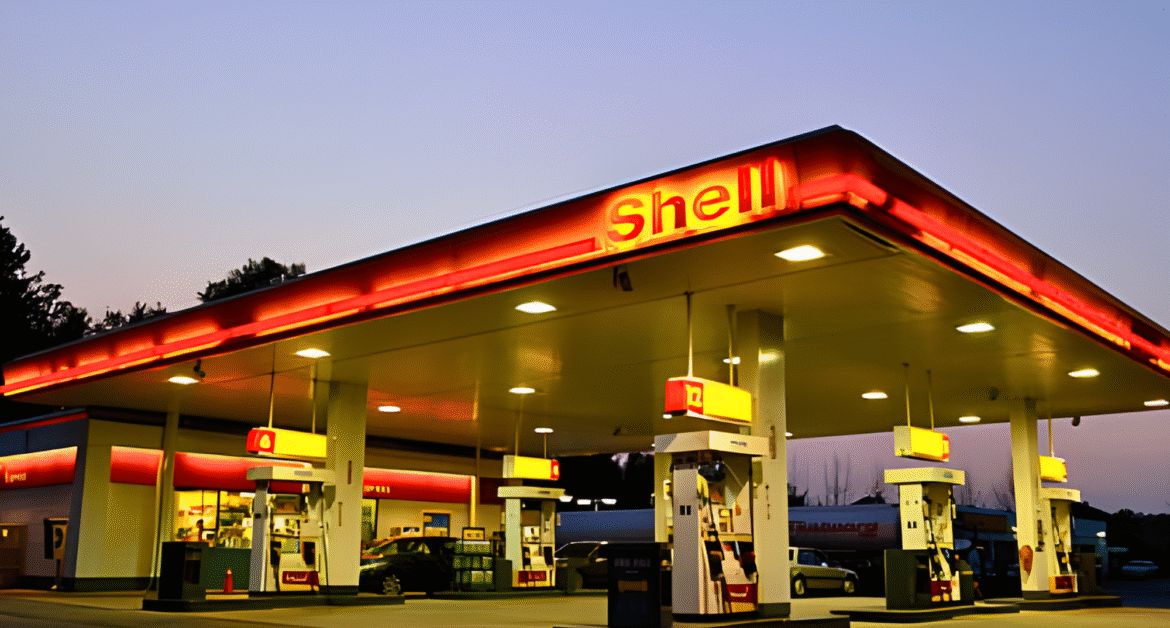

SHELL PETROLEUM SITES – ELECTRICAL SAFETY & TESTING PROJECT

For this large-scale initiative, Gratify Engineering (PVT) Ltd partnered with Shell Petroleum to deliver comprehensive electrical testing and safety inspections across more than 560 sites. Our team implemented advanced thermography, insulation, earthing, and leakage testing techniques to proactively identify issues, optimize system performance, and strengthen workplace safety.

This project highlights our expertise in industrial-scale safety testing and fault detection, proving our ability to handle complex and multi-location projects with precision and reliability.

Our Main Goals

At Gratify Engineering (PVT) Ltd, we believe that safety and reliability are the foundation of all successful electrical systems. For Shell Petroleum, our mission was to deploy advanced testing methods that minimized risks, ensured compliance, and supported uninterrupted energy operations.

With expertise across 560+ sites, we conducted insulation testing, thermography, and earthing inspections to detect potential faults, improve performance, and ensure maximum safety. Current leakage testing was also performed to safeguard critical operations.

1

Fault Detection

Insulation and leakage tests identified hidden risks before they became failures.

2

Thermal Scanning

Thermography ensured equipment operated safely under varying loads.

3

Earthing Assurance

Verified earthing integrity for stable and safe electrical distribution.

4

Safety Optimization

Delivered enhanced operational safety across 560+ petroleum sites.